In the year 1836, Stanilaus Tranquille Modeste Sorel, another French chemist, patented the methods of iron plating by means of zinc and cleaning with 9% sulfuric acid and surface preparation through ammonium chloride. One year later, in 1837, the British Patent Institute approved this method. One year later, in 1837, the British Patent Institute approved this method. In 1850, the British galvanizing industry performed galvanisation of 10,000 tons/year. In the first years, galvanisation was used to protect large steel structures against corrosion. Due to the fact that the steel structures which are subjected to galvanisation before installation receives protection against easy rusting of steel and thus gains a longer service life, galvanisation has begun to be used especially for steel power transmission lines built in hard-to-reach places. In the course of time, the use of steel in the world has increased as the steel became easier to process thanks to technological developments, and as the use of steel increased, galvanizing also increased in parallel.

The increase in the production of steel before the hot war years led to the development of the defence industry. The ever-increasing capacity has gradually increased in connection with different sectors. The USA and many developed European countries made the industrial revolution primarily through steel.

Today, there are magnificent examples of steel structures throughout Europe remained from those years. And of course, almost all of these steels are galvanized. For about 150 years, all kinds of steels whose compositions are suitable for galvanisation have been galvanized at increasing rates. Galvanising has become indispensable for many sectors today.

At Which Areas Is Hot-Dip Galvanised Coating Used?

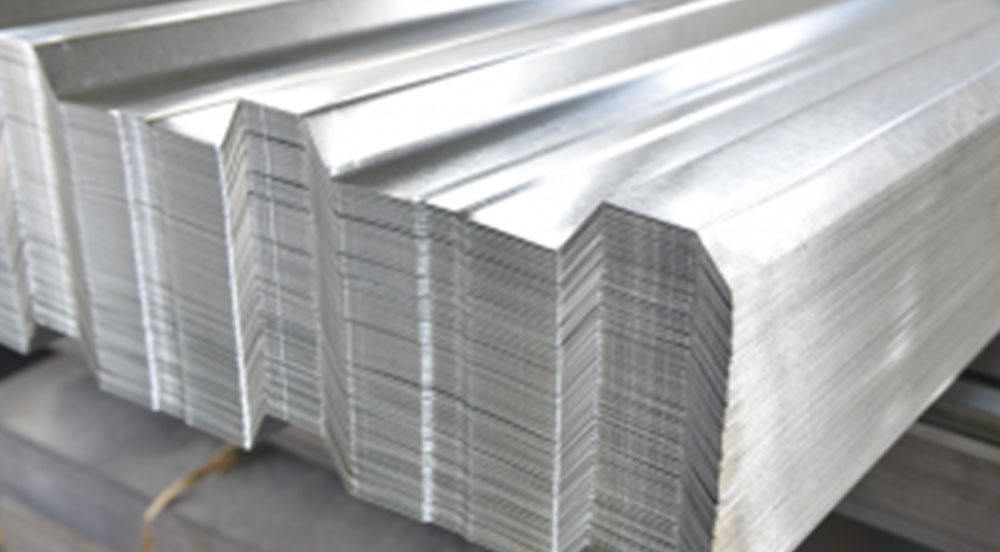

Hot-dip galvanised steels (elbows, channels, wide-cap beams, I-section beams, H-section beams) can be used in cages, expanded metals (waste basket, bench benches), corrugated sheets, plates, castings, pipes and the materials, through which pipes are made.

Moreover, hot-dip galvanised steels can be used in concrete reinforcing bars for staging and concrete columns on bridges and highways, poles, longitudinal beams, lights and road signs, roadside barriers, fences, water and wastewater treatment plants, sidewalk railings and handrails, and building facades, outdoor structural steels, reinforcing bars for reinforced concrete columns, structural steels and barriers that are located outdoors, engine housings, electrical panels, pulleys, heat exchanger coils, transmission towers in electrical assemblies, distribution line polygons, transformers, wind turbines, communication poles, rail transportation, pipeline equipment, manufacturing buildings storage tanks, passages in the architecture, and in countless other places which we cannot list here.

WHY GALVANISED MATERIALS?

- AFFORDABLE

- DURABLE

- RELIABLE

- ENVIRONMENT-FRIENDLY

- COST-EFFICIENT

- CATHODIC PROTECTION

- SAVING OF TIME

- FULL COATING

- CONVENIENCE